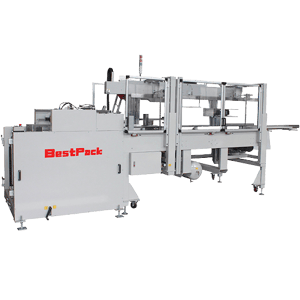

From fully manual carton sealers to fully automated ones, CS Packaging has a wide variety of Carton sealers to fit the needs of your business.

Basics of Carton Sealer:

- - Tape machine that tapes either the bottom of the box, the top, or both

- - These machines can be purchased as manual or automatic, and the features depend on the level of customization needed. Some are for very basic applications, (such as the same carton going through repeatedly), while some use fully automatic and pneumatic systems to integrate into automated packaging lines for all different box sizes

.png?width=845&height=137&name=Slice%203%20(23).png)

.png?width=280&name=unnamed__13_-removebg-preview%20(1).png)