Retention inserts and suspension packaging eliminate risk and worry. Yes, product packaging isn’t too much of an issue for soft goods that are purchased online, but for expensive, fragile things like computers, it’s a different story.

After all, packages get tossed around, might be dropped or even stacked on top of one another as they go from Point A to Point B.

The last thing you want to do is have to worry about returning a damaged or busted product upon home delivery. And that’s where retention and suspension packaging comes into play.

How Does Suspension Packaging Work?

Retention and suspension packaging uses special corrugated inserts and plastic flexible film. The inserts fit into the shipping box and work to suspend the product so that it’s more centrally located within the open airspace of the box and away from the major points of impact.

Additionally, the product is secured into place with plastic flexible film, which prevents it from slipping around or moving within the box itself.

What Are the Benefits of Suspension Packaging?

- - Customizable.

- - Reusable.

- - Impresses customers.

- - Is easy to assemble and install.

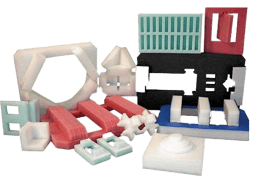

There are several benefits to using retention and suspension packaging. For starters, it presents a more cost-effective alternative to conventional means of secure shipping, which often involves the use of foam, die-cut molds, or other materials.

Here’s a look at some of the key benefits to this type of packaging:

1. It’s easily customizable:

Because products are secured in place with flexible plastic film, most retention and suspension packaging is a one-size-fits-all type of solution thanks to the conforming properties of the film itself.

2. It’s reusable:

The flexible film used to hold products can be easily reused, as it maintains its effectiveness. Noting this, it’s a more eco-friendly option.

3. It looks great:

On most packages you’ve opened over the years, you likely had to dig through the box and break apart foam to get to the product you bought.

This creates a bit of a mess that you’re left to clean. When you open a box with retention and suspension packaging, you’re able to see the product right then and there as soon as the box is opened.

There’s no digging around or messy cleanup. In fact, the corrugated retention inserts can be recycled too.

4. It’s easy:

Retention and suspension packaging is easy to assemble and install.

.png?width=845&height=137&name=Slice%203%20(23).png)

Air cushion packaging uses an inflatable cushioning system within a box to protect a package's contents from damage during shipment.

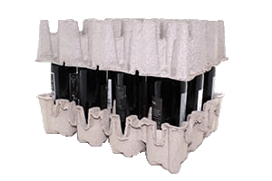

Air cushion packaging uses an inflatable cushioning system within a box to protect a package's contents from damage during shipment. Molded pulp packaging is a newer type of packaging typically made from recycled materials. It is used for protective packaging mostly for food and beverages.

Molded pulp packaging is a newer type of packaging typically made from recycled materials. It is used for protective packaging mostly for food and beverages.

Let's say your product has a

Let's say your product has a